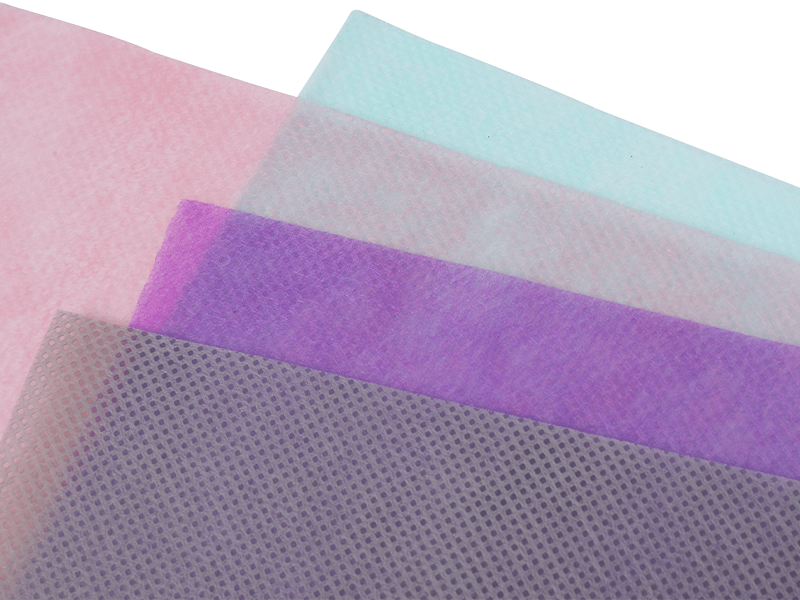

Nel mondo del tessile, la scelta del tessuto gioca un ruolo cruciale nel determinare la funzionalità, il comfort e la durata del prodotto finale. Tra le varie tipologie di tessuti oggi disponibili, tessuto non tessuto elastico è emerso come un'opzione versatile e pratica sia nelle applicazioni industriali che di consumo. A differenza dei tessuti tradizionali, i tessuti non tessuti elastici vengono prodotti utilizzando diverse tecniche di lavorazione che conferiscono loro proprietà uniche.

Comprensione del tessuto non tessuto elastico

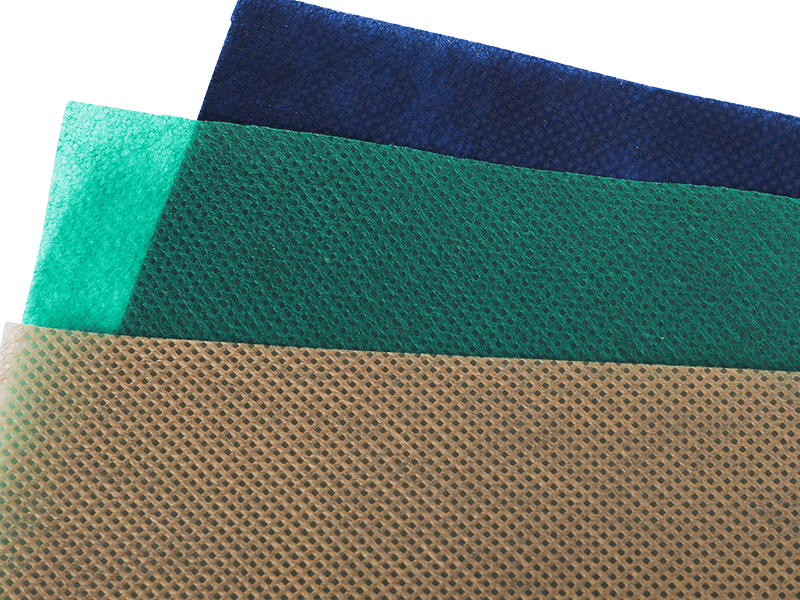

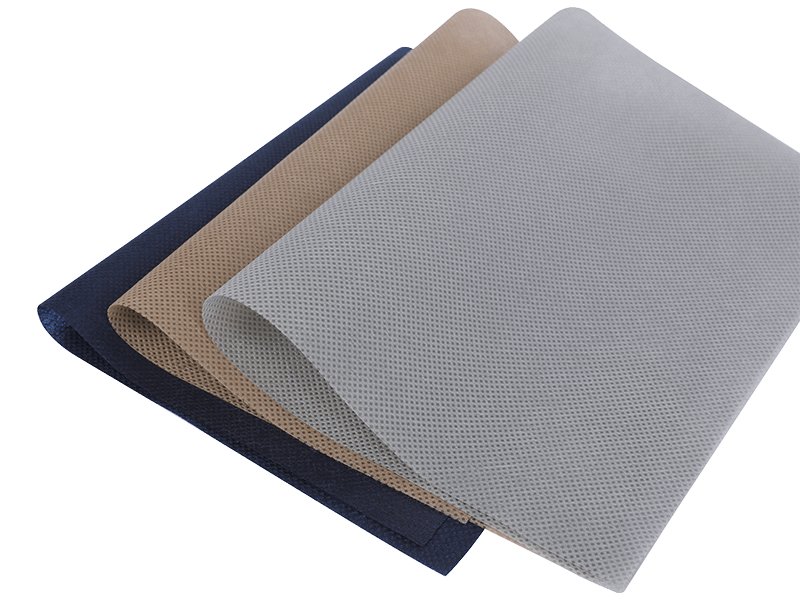

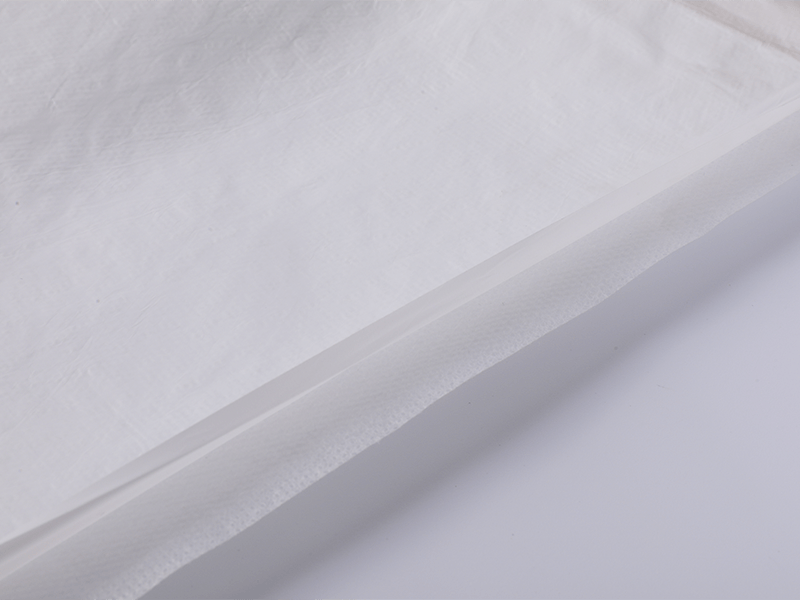

Prima di parlare dei suoi vantaggi è fondamentale capire cos’è il tessuto non tessuto elastico. I tessuti non tessuti sono tessuti tecnici costituiti da fibre legate insieme mediante processi meccanici, chimici o termici, anziché essere tessuti o lavorati a maglia. Quando questi tessuti sono combinati con fibre o materiali elastici, acquisiscono elasticità, flessibilità e resilienza, rendendoli adatti per applicazioni che richiedono adattabilità e comfort.

I tessuti non tessuti elastici sono utilizzati in un'ampia gamma di prodotti, tra cui forniture mediche, prodotti per l'igiene, indumenti protettivi, tessili per la casa, applicazioni industriali e altro ancora. Le loro proprietà, come traspirabilità, struttura leggera ed elasticità, li differenziano dai tessuti convenzionali.

Vantaggi chiave del tessuto non tessuto elastico

1. Flessibilità ed elasticità superiori

Uno dei vantaggi più significativi del tessuto non tessuto elastico è la sua flessibilità intrinseca. A differenza dei tessuti, che hanno un intreccio fisso di fili di ordito e di trama, i tessuti non tessuti possono allungarsi in più direzioni a seconda del tipo e della disposizione delle fibre. Quando vengono incorporate fibre elastiche, il tessuto può ritornare alla sua forma originale dopo l'allungamento, fornendo comfort e adattabilità in applicazioni quali abbigliamento, bende e prodotti igienici usa e getta.

Ad esempio, negli indumenti medici o nei camici chirurgici, il tessuto non tessuto elastico consente facilità di movimento, riducendo il disagio sia per gli operatori sanitari che per i pazienti. Allo stesso modo, nei pannolini o nei prodotti per l'incontinenza degli adulti, l'elasticità garantisce una perfetta aderenza senza compromettere il comfort.

2. Leggero e confortevole

I tessuti non tessuti elastici sono generalmente più leggeri dei tessuti tessuti a causa della loro rete di fibre sciolte e della minore densità del materiale. Questa natura leggera migliora il comfort, in particolare in applicazioni come indumenti usa e getta, maschere e biancheria da letto. Mentre i tessuti intrecciati possono sembrare più pesanti e meno flessibili, i tessuti non tessuti elastici forniscono una consistenza morbida e ariosa che si adatta ai movimenti del corpo.

Inoltre, il peso ridotto dei tessuti non tessuti può ridurre i costi di trasporto e il consumo di energia durante la produzione, rendendoli una scelta più pratica e rispettosa dell’ambiente in molti scenari.

3. Eccellente traspirabilità e gestione dell'umidità

I tessuti non tessuti elastici spesso presentano una struttura porosa che consente all'aria e all'umidità di passare facilmente. Questa traspirabilità è particolarmente vantaggiosa nei prodotti che entrano in contatto diretto con la pelle, come maschere mediche, prodotti per l'igiene e abbigliamento sportivo.

In confronto, i tessuti con fili fitti possono limitare il flusso d’aria e trattenere l’umidità, causando disagio, irritazione o problemi alla pelle in caso di uso prolungato. La capacità dei tessuti non tessuti elastici di gestire l’umidità mantenendo l’elasticità li rende adatti per applicazioni sanitarie e ad alte prestazioni.

4. Maggiore efficienza produttiva

I tessuti non tessuti elastici possono essere prodotti in modo più rapido ed economico rispetto ai tessuti tessuti. La tessitura tradizionale richiede un'impostazione approfondita, compresa la preparazione del telaio e l'intreccio dei fili, che può richiedere molto tempo e manodopera. I tessuti non tessuti, tuttavia, vengono prodotti utilizzando processi come spunbonding, meltblowing o agugliatura, che consentono una produzione continua e una maggiore uniformità.

Questa efficienza si traduce in costi di produzione inferiori, tempi di consegna più rapidi e capacità di soddisfare richieste di volumi elevati, vantaggi particolarmente preziosi per i prodotti usa e getta o monouso.

5. Proprietà personalizzabili

I tessuti non tessuti elastici offrono un elevato grado di personalizzazione. I produttori possono regolare il tipo di fibra, lo spessore, la densità e i metodi di legame per ottenere caratteristiche prestazionali specifiche, come elasticità, morbidezza, resistenza alla trazione o proprietà barriera. I tessuti, d'altro canto, sono più vincolati dai tipi di filo e dai modelli di trama, limitando la flessibilità delle loro proprietà funzionali.

Ad esempio, negli indumenti protettivi, i tessuti non tessuti elastici possono essere progettati per fornire resistenza a fluidi, batteri o particolati, pur mantenendo elasticità e comfort. Questo livello di personalizzazione è difficile da ottenere con i tessuti convenzionali.

6. Riduzione dello sfilacciamento e degli sprechi

Poiché i tessuti non tessuti sono realizzati unendo le fibre anziché intrecciandole, non si sfilacciano ai bordi quando vengono tagliati. Questa caratteristica semplifica i processi di produzione, riduce gli sprechi di materiale e minimizza la necessità di ulteriori fasi di finitura come l'orlatura. I tessuti, al contrario, spesso richiedono la rifinitura dei bordi per evitare lo sfilacciamento, con conseguente aumento di manodopera, tempo e costi.

Per le industrie che producono prodotti usa e getta o monouso, la ridotta sfilacciatura del tessuto non tessuto elastico rappresenta un vantaggio significativo, garantendo qualità e durata costanti nella produzione di massa.

7. Morbidezza e delicatezza sulla pelle

I tessuti non tessuti elastici sono generalmente più morbidi dei tessuti tessuti, poiché possono essere realizzati con fibre fini e progettati per essere morbidi. Questa proprietà li rende adatti per applicazioni a diretto contatto con la pelle sensibile, come pannolini per bambini, maschere facciali o medicazioni per ferite. I tessuti, a seconda della trama e del tipo di fibra, possono sembrare ruvidi o rigidi, rendendoli meno adatti a tali applicazioni.

Inoltre, la morbidezza dei tessuti non tessuti elastici contribuisce al comfort di chi indossa i prodotti medici e igienici, riducendo le irritazioni e migliorando la compliance dell'utente.

8. Proprietà barriera e protettive

I tessuti non tessuti elastici possono essere progettati per fornire funzioni barriera specifiche, come idrorepellenza, resistenza chimica o filtrazione microbica. Ciò li rende ideali per indumenti protettivi, camici chirurgici, maschere e applicazioni industriali. Anche i tessuti possono offrire protezione, ma per ottenere lo stesso livello di prestazione barriera spesso sono necessari rivestimenti o trattamenti aggiuntivi, che possono ridurre la traspirabilità e il comfort.

Ad esempio, gli strati non tessuti soffiati a fusione nelle maschere e nei respiratori forniscono una filtrazione fine delle particelle mantenendo elasticità e comfort, proprietà difficili da replicare con i soli tessuti.

9. Rapporto costo-efficacia per i prodotti usa e getta

Nelle applicazioni in cui è richiesto un utilizzo monouso o a breve termine, i tessuti non tessuti elastici offrono notevoli vantaggi in termini di costi. Sono generalmente meno costosi da produrre rispetto ai tessuti, soprattutto per articoli ad alto volume come camici medici, teli chirurgici o prodotti per l'igiene. La combinazione di basso costo, elasticità e funzionalità li rende la scelta preferita nei settori che richiedono prodotti usa e getta o semi-usa e getta.

10. Versatilità tra i settori

I tessuti non tessuti elastici hanno un’ampia applicabilità in molteplici settori. Sono utilizzati in:

- Medicina e sanità : camici chirurgici, maschere, medicazioni per ferite, bende.

- Prodotti per l'igiene : pannolini, prodotti per l'incontinenza degli adulti, articoli per l'igiene femminile.

- Indumenti protettivi : uniformi industriali, tute di protezione chimica, camici da laboratorio.

- Beni di consumo : biancheria da letto, coprimaterassi, filtri, sacchetti riutilizzabili.

- Applicazioni automobilistiche e industriali : isolamenti, geotessili, materiali da imballaggio.

Sebbene i tessuti continuino ad essere importanti nell'abbigliamento, nella tappezzeria e in alcuni usi industriali, l'adattabilità dei tessuti non tessuti elastici conferisce loro un vantaggio nelle applicazioni che richiedono elasticità, morbidezza e praticità di utilizzo.

Conclusione

Il tessuto non tessuto elastico offre numerosi vantaggi rispetto ai tessuti tradizionali, tra cui flessibilità superiore, comfort leggero, traspirabilità e caratteristiche prestazionali personalizzabili. La sua efficienza produttiva, la ridotta sfilacciatura, la morbidezza, le proprietà barriera e il rapporto costo-efficacia per le applicazioni usa e getta ne aumentano ulteriormente l'attrattiva. Sebbene i tessuti siano indispensabili in molti settori, i tessuti non tessuti elastici forniscono soluzioni in cui elasticità, comfort e funzionalità sono fondamentali.

Comprendendo questi vantaggi, produttori, designer e consumatori possono fare scelte informate nella scelta dei tessuti per applicazioni mediche, igieniche, industriali o di consumo. La versatilità e le prestazioni del tessuto non tessuto elastico lo rendono un'alternativa pratica e affidabile ai tessuti in molti scenari, plasmando il futuro dei tessuti moderni.